Cutting

Cutting has become the industrial standard for the production of joints, washers, medical components, vehicle parts...

Cutting

Cutting has become the industrial standard for the production of joints, washers, medical components, vehicle parts...

Cutting has become the industrial standard for the production of joints, washers, medical components, vehicle parts...

The cutting, tailor-made on all materials

Cutting for flat products.

Cutting is a highly versatile manufacturing process. We have three types of cutting methods:

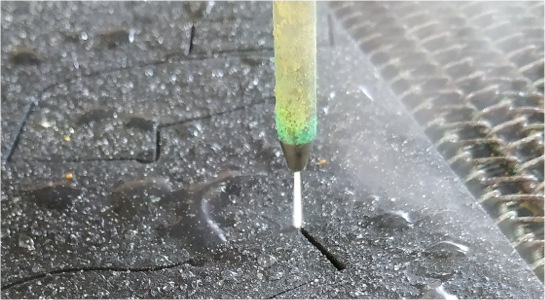

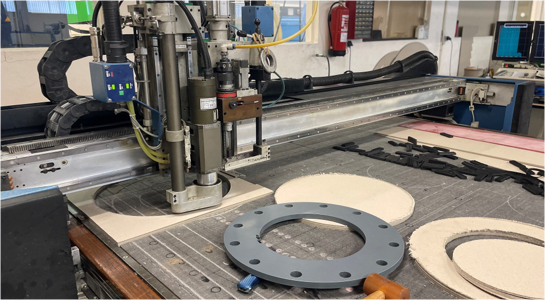

• High-pressure water jet cutting, which enables precise cutting of materials of varying thickness.

• Cutting using a fast-moving blade on a cutting table to cut through sheets.

• Die cutting, used to cut shapes in flexible or less rigid materials. It consists of a sharp steel blade formed by bending or machining.

The combination of these technologies enables cutting of flexible, rigid, cellular, and even rubber/metal composite materials. From standard gaskets to custom-made ones, we can accommodate all dimensions.

We can also produce large-sized flat gaskets by combining the cutting of sectors and their assembly through hot vulcanization or bonding.

ELADIS offers adhesive application on rolls or sheets prior to cutting and/or selective cutting.

The combination of these technologies enables cutting of flexible, rigid, cellular, and even rubber/metal composite materials. From standard gaskets to custom-made ones, we can accommodate all dimensions.

We can also produce large-sized flat gaskets by combining the cutting of sectors and their assembly through hot vulcanization or bonding.

ELADIS offers adhesive application on rolls or sheets prior to cutting and/or selective cutting.