Materials

Known for their elasticity, flexibility, and resistance, we often refer to rubber when we should be talking about rubbers, given the vast family of elastomers.

Materials

Known for their elasticity, flexibility, and resistance, we often refer to rubber when we should be talking about rubbers, given the vast family of elastomers.

Known for their elasticity, flexibility, and resistance, we often refer to rubber when we should be talking about rubbers, given the vast family of elastomers.

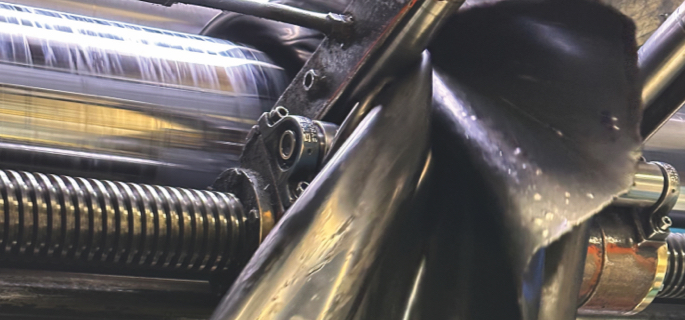

Transforming the material

Exploited primarily in Asia since the 15th century, natural rubber was joined by the first synthetic rubbers in the early 20th century. Since then, industrial development has led to the production of increasingly advanced rubber materials.

The cross-linking of rubber, the chemical transformation of the material, is an irreversible reaction. This process, achieved by prolonged heating of the material during the vulcanization stage, removes the rubber's plasticity and imparts new properties. The initial step in rubber transformation involves the formulation of a mixture, which is tailored to meet mechanical and chemical constraints as well as customer requirements, such as drinking water approval. Generally, a rubber compound consists of four main components:

rubber, additives, fillers, and plasticizers.

With our expertise, we can help you bring your projects to fruition by selecting the most suitable material for your specifications:

Traditional Rubbers

NR, SBR, CR, NBR, EPDM, ETP, IIR

Technical Elastomers

H/NBR, ACM, ECO, Vamac, Silicone, Viton,

FKM, as well as polyurethanes

Thermoplastic Rubbers

Santoprene, SBS, SEBS, PP-EPDM

Rigid or flexible PVC, ABS